back to Pinnacle safety products | ||||

|

MicroGuardŽ Safety Light Curtain |

|||

|

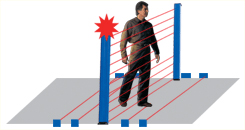

Body Detection MicroGuardŽ Safety Light Curtain The Body Detection MicroGuardŽ is designed to guard entry/exit areas in hazardous work cells. It utilizes the standard Metal Box (MG) or DIN-Rail Mount (DR) controller and provide coverage heights from 16" to 124". Standard scanning distances of 20' apply, with extended range units shooting up to 35' on a straight scan. The sensing fields consist of a four inc, one inch beam spaced board, then an eight inch inactive or spacer board, then a four inch, one inch beam spaced board and so on. The minimum object sensitivity is nine inches, in other words "Body Detection". All optional features can be utilized with the Body Detection MicroGuardŽ. The most common will be the Guarding Mute-Out (MO) to allow conveyed material to pass through the MicroGuardŽ sensing field but will not allow a person to walk into the hazardous area. The following examples describe the functionality of the MicroGuardŽ in conjunction with muting sensors in entry/exit guarding applications.

| |||

|

MicroGuard® Model SS Safety Light Curtain The Model SS is an infrared safety light curtain that is designed to the IEC 61496 standard. When properly installed, it protects the machine operator by passing an invisible infrared light beam across an area to be guarded and examining whether or not the light beam(s) are blocked. If the light beam(s) are blocked, monitored solid state outputs will open, issuing a “STOP” command to the machines normally closed (N.C.) “STOP” circuit. The System is composed of a transmitting unit (EMITTER), and a receiving unit (RECEIVER). The entire system is control reliable Category 4 (per IEC 61496). A single fault anywhere within the Model SS will not prevent at least one of the solid state outputs from opening up, (allowing a “STOP” command) when either a beam is broken or an internal fault occurs. |

|||

|

SLT Series Safety Light Curtain Standard on all safety light curtains is the revolutionary front panel diagnostic display. The bright red alphanumeric LED display shows the status of the safety light curtain along with various integral fault codes relating to the maintenance and operation of the system. The diagnostic display monitors microprocessors, captive contact safety relays, bad grounds, external infrared sources, shorts, blanking, etc. Fault conditions are easily read and displayed on the top front panel of the receiver pylon. These easy to read external diagnostic codes and status displays will enhance safety and machine utilization by minimizing machine downtime and set up time measurably. The advanced design of the SLT (Safety Light Technology) Series diagnostics will also count and display the number of beams blanked out in the "Auto-Blank" mode. This is an important feature when computing the depth penetration factor required for proper installation. A detailed definition, status, reason(s), and cure listing is provided in the installation and operation manual of the SLT Series safety light curtain.

| |||

|

PPG Perimeter Guards Perimeter Guards utilize wider beam spacing than safety light curtains protecting personnel from "pinch point" or "point of operation" hazard zones. Perimeter Guards are designed to detect when an operator or passerby penetrates the perimeter of a hazardous zone. The Perimeter Guard safety light curtain will then initiate a stop signal to the machine control. Perimeter Guards also incorporate latching safety relays. This requires a manual reset after each penetration into the guarded zone. This is an additional safety feature to protect the intruder from an inadvertent machine actuation while the intruder is within the work area. | |||

|

||||

|

|---|