|

|

|

|

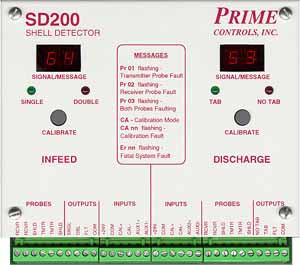

SD200

Double Shell and Missing Tab Detector

"Great for a stay-on-tab conversion press "

Over 2200 installed

At the touch of a fingertip, the New Model SD200 and its push-to-calibrate feature, provides a simple and dependable way to begin monitoring can ends traveling through your conversion press. The Model SD200 is two detectors in one for use on each lane of a conversion press.

This Double or Nothing detector, along with two sets of probes installed at the infeed and discharge of each lane, will detect a double shell and missing tab. Each channel has three solid-state outputs. The three Infeed (shell) outputs energize for single, double and fault conditions. The three Discharge (tab) outputs energize for tab present, no tab and fault conditions.. |

Calibrating the detector for your application is simply done by pushing either of the Calibrate push buttons on the front of the detector. To calibrate, you insert a single shell between the probes and push the button on the Infeed channel. It will automatically set the threshold levels for passing singles and rejecting doubles. Then, you insert an end with a tab between its probes and push the button on the discharge channel. It will automatically set the level for tabs and reject a shell missing a tab. Calibration is completed that easily. The detector is ready to protect expensive conversion tooling.

There are no additional adjustments or fine tuning. It will automatically optimize itself, if possible, to function in the application. Dual two-digit LED displays report relative thickness, probe signal strength and diagnostic fault conditions. The detectors are housed in one rugged metal chassis. Quick disconnect terminals will provide fast and easy changeover. The operating power requirement for the Model SD200 is standard 24 Volts DC.

Need two Shell Detectors? Consider SD202

Need two Tab Detectors? Consider SD203 |

|

| |

Features

- Push-button calibration optimizes settings and reduces time to set up.

- Microprocessor control provides better measuring resolution and reliability.

- Aluminum & Steel sensitivity eliminates the need to stock more than one model.

- Two detectors in one chassis provides a compact package and requires less panel space.

- Two digital displays to monitor relative thickness, signal strength and fault conditions.

- Diagnostic messages quickly isolate errors and failures in the detector and probes.

- Operating Power is standard 24 Volts DC.

- Six solid state transistor outputs for comprehensive control of Single. Double, No Tab, Tab & Channel Fault detection.

- Quick disconnect terminals decrease replacement downtime

- Functionally compatible with early Prime & Hyde Park Models DS33, DS35, DS37,and DS38 and will fit in the same panel footprint.

|

- Power Input: (required), Voltage: 24 V DC *10 % ripple Current: >350 mA.

- Logic Inputs external designated Calibration and Auxiliary 1 & 2. Hardware consists of jumper selected transistor type : pull-up mode for source drivers, pull down for sinking drivers. (AUX. changes frequency to steel or aluminum optimum sensitivity)

- Logic Impedance is 4.7K ohms, response to less than 1 m Sec.

- Switching thresholds: above 6.4V when going high, below 5 volts when going low.

- Probe Inputs tuned for Prime transmitter and receivers only for each channel.

- Outputs (6) Transistor types, designated Single, Double, Tab, No-Tab, 2-Fault Jumper select current sinking or source Source current limit at 160 mA, combined outputs. Source voltage: 22 Volts Sinking current: 100 mA Max. Sinking voltage: 30 Volts Max.

- Probe Types AY, AV, AZA, CB, CFB and all in P15 family for optimal operation, also works with AK, AVB, CA, CF and P70 family but not optimized for best operation.*

- Response Time 1 to 16 m Sec (Effected by the metal type and the thickness during calibration).

- Thickness Range 1 mm (.040") with P15CS, Varies with probe and separation.

|

- Probe Separation max 75 mm with P15CS.

- Max range not advisable when trying to detect pull tab. For pull tab detection use any of the probe types recommended under Probe Types with 16 mm (.625") separation. Do not use probes ending with S.

- Reject threshold. Factory set to 50% ON and 30% OFF of calibrated nominal.

- Displays Two channel, two digit alphanumeric LED display. During operation indicates signal strength and fault location. During calibration nominal value or calibration fault.

- Indicator Lamps consist of two channels of green for present and red for over or under nominal value. Also flash for faults.

|

|

|

|