|

|

|

|

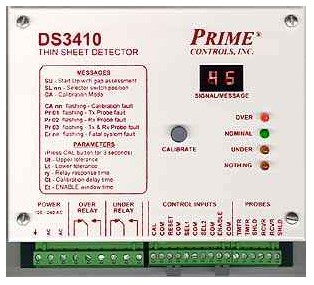

DS3410

Dual Probe Double Metal Detectors for Non-Ferrous Metals

THIN METAL DETECTOR

Used to Detect Double Printed Circuit boards, Double Stainless Steel, Blister Pack Verification

The Model DS3410 Thin Metal Thickness Detector is easy to operate. There are relay outputs for Over, Under, Normal thickness and Nothing present. Up to eight separate thickness values are stored and recalled later through a remotely located selector switch module. It measures nonferrous metals under .025 mm (.001") thickness.

Calibration is simple. Place a metal sheet between the probe assembly and push the Calibration button. That's all. It calculates the double thickness and sets the reject threshold. The detector sets it’s reject threshold to 50% between the first and calculated second thickness. As a double metal detector the Model DS3410 discriminates single, double, and no-metal conditions. |

Ideal for monitoring up to ten blister packages in a closed carton |

|

Two value Calibration permits higher gauging precision. This option is selectable via a DIP switch located under the front cover. Rather than having the DS3410 calculate the double reject value, the user teaches the detector the nominal value and then a reject value. This permits the user to control the range of the monitored thickness. Through this feature the range is narrowed (< Double) or expanded (> Double).

The DS3410 features has adjustable reject thresholds. The adjustment ranges from 1 to 99%. Adjust the reject thresholds by holding the Calibration button for three seconds until a sub menu is displayed. The display prompts either OT (over thickness) or UT (under thickness). The value is changed after letting up on the button when one of these appropriate fields are displayed. Further pressing of the button advances the values. Once at 99 the display will roll-over to 01. The detector returns to the run display after the button is inactive for six seconds.

An Enabled Timer feature is used to limit the inspected region on a printed circuit board or other thin metal. For example, an application with a post-etched circuit board uses this feature to look for a specific area or region as each board travels through the inspection probes on a conveyor. The timer window is adjustable for .01 to .99 seconds. |

The Timer is Enabled when a contact closes across a set of input terminals (labeled ENABLE). The Timer remains on for the adjusted period. A switch, proximity or similar device is used as the Enable trigger. For example, a ultrasonic or photoelectric sensor is located to detect the lead edge of the circuit board when a specific area is positioned between the thickness measuring probes.

Nonvolatile memory stores all settings if power is lost. Its a great value. |

|

| |

| Dual Probe Double Metal Detectors for Non-Ferrous Metals |

Features

|

|

- Power Input: 100 to 240 VAC, 50/60 Hz 300 mA operating load

- Output: 2 SPDT contact relays Max load: 10 Amps @ 240 V AC 8 Amps @ 24 V DC ½ HP @ 240 V AC

- Output Fail-safe: Defaults to reject w/power off

- Output Response: adjustable to < .030, .100, .500, 1 second

- Thickness Range: .5 to 2 ounce copper plate, nonmagnetic stainless steel. (for magnetic SS see our latest DS1500 Family)

- Probes: All probes beginning with P1C, P1CS, type "AX"

- Probe Separation: 12 mm to 75 mm (.5 to 3”) or more. Max. varies w/(metal, thickness & probe, separation). Maximum range is realized with Model P1CS transmitter & receiver probes.

|

- Calibration Methods: Push-button switch used to measure thickness between probes during calibration. Manually place sample between probes, push Calibration button.

- Enable Input: enables inspection timer.

- Over and Under Reject Threshold: factory set at 50% between nominal and calculated double. Reject threshold may be changed by user over a range of 1 to 99%

- LED Indicators: Green for single, Amber for Over, Under & Nothing detected.

- Display Indication: 2 digit LED, alphanumeric, .5 inch high. Setup menu, calibration mode, operating probe signal strength, fault codes

- Sensor Operation: Eddy Current in metal impedes signal from transmitter to receiver. Impedance changes as metal thickness changes.

|

|

|

|