|

|

|

|

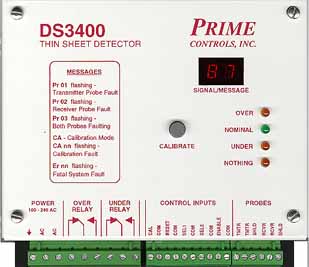

DS3400

Dual Probe Double Metal Detectors for Non-Ferrous Metals

"Great Thickness Monitor for Copper Circuit Boards, Nonmagnetic Stainless Steel, >1 mil Aluminum Foil Packets"

The Model DS3400 is an easy to operate Thin Metal Thickness Detector. Control outputs are available for Over, Under, Normal thickness and Nothing present.

Up to eight separate thickness values are stored and recalled later through a remotely located selector switch module. Nonferrous metals under .025 mm (.001") thickness are measurable for variations |

Calibration is simple. Place a metal sheet between the probe assembly and push the Calibration button. That's all. It calculates the double thickness and sets the reject threshold. The detector sets it’s reject threshold to 50% between the first and calculated second thickness.* The display prompts either OT (over thickness) or UT (under thickness). As a double metal detector the Model DS3400 discriminates single, double, and no-metal conditions. Nonvolatile memory stores all settings if power is lost. Its a great value.

The DS3400 discriminates between .1/2, 1, & 2 ounce copper. It also detects 4 ounce copper. However this increased thickness is detectable with most of our other double metal detectors, including Prime's general purpose Model DS150.

* Go to our Model DS3410 for applications where the required detectable thickness difference is less than double (50% of nominal). For example: if the detectable difference is between 1 and 1.5 ounce or .5 to .8 ounce copper plate. The Model DS3410 has adjustable reject thresholds that range from 1 to 99% of the nominal thickness. In addition the DS3410 permits two sample calibration. Both the nominal and reject values are manually entered through the pushbutton teach feature. |

|

| |

| Dual Probe Double Metal Detectors for Non-Ferrous Metals |

Features

- Ultra-sensitive to very thin nonferrous metals. For example 1/4 ounce copper, less than 1 mil aluminum

- Pushbutton Teach Calibration

- Store up to eight thickness calibrated values

- Automatic signal strength adjustment and probe identification at start-up

- Self diagnostic messages quickly isolate system problems, errors and failures

- Operating Power 90 - 240 Volts AC @ 50-60 Hz.

- Compact Size, (210 mm x 170 mm x 50 mm) to fit in tight spaces

- Quick connect terminals for fast replacement and to reduce downtime

-

Latched or momentary output

-

Output relay response less than 10 mS

- Separate SPDT output relays for Over and Under

- Four possible logic output combinations for Over, Under, Nominal and Nothing

|

|

- Power Input: 100 to 240 VAC, 50/60 Hz 300 mA operating load Output: 2 SPDT contact relays Max load: 10 Amps @ 240 V AC 8 Amps @ 24 V DC ½ HP @ 240 V AC

- Output Fail-safe: Defaults to reject w/power off

- Output Response: adjustable to < .030, .100, .500, 1 second

- Thickness Range: .5 to 2 ounce copper plate. Up to Nonmagnetic Stainless Steel. (for Magnetic SS see the latest DS1500 family detector)

- Probes: All probes beginning with P1C, P1CS, type "AX"

- Probe Separation: 12 mm to 75 mm (.5 to 3”) or more. Max. varies w/(metal, thickness & probe, separation). Maximum range is realized with Model P1CS transmitter & receiver probes. .

|

- Calibration Methods: Push-button switch used to measure thickness between probes during calibration. Manually place sample between probes, push Calibration button.

- Enable Input: enable output.

- Over Reject Threshold: 50% between two sample calibration. Under threshold via 50% interpolation

- LED Indicators: Green for single, Amber for Over, Under & Nothing detected.

- Display Indication: 2 digit LED, alphanumeric, .5 inch high. Setup menu, calibration mode, operating probe signal strength, fault codes

- Sensor Operation: Eddy Current in metal impedes signal from transmitter to receiver. Impedance changes as metal thickness changes.

|

|

|

|