|

|

|

|

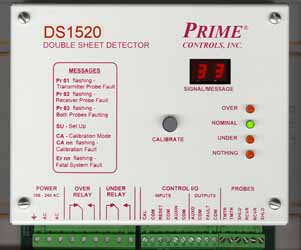

DS1520

Dual Probe Double Metal Sheet Detectors

"Great for Frequent Gauge Changes, NOMINAL Thickness Monitor and Thickness Classification"

AUTOMATIC & PUSHBUTTON TEACH CALIBRATION

DETECT OVER,UNDER, NORMAL AND NOTHING

DIGITAL DISPLAY FOR SENSITIVITY & DIAGNOSTICS REJECT THRESHOLD ADJUSTABLE

STORE UP TO 10 SEPARATE THICKNESS JOBS

The Model DS1520 is an easy to operate dual probe metal thickness detector. Variations in thickness as small as 1% are detectable. Control outputs are available for OVER, UNDER, Normal thickness and NOTHING present. Up to ten separate thickness values can be stored and recalled later through a remotely located selector switch module. Ferrous and nonferrous metals over a range of .05 mm to 8 mm (.002” to .300”) may be monitored with Prime’s sensing probes. |

Calibration is simple. Select a memory switch position. Place a metal sheet between the probe assembly and push the calibrate button. Add another sheet between the assembly and push the button again. The second sheet does not have to be the same thickness. Repeat both steps for up to ten separate sheet sizes. After calibration, the detector sets it’s reject threshold to 50% between the first and second thickness. Even the 50% default reject threshold setting is manually adjustable by holding the calibrate button in for 3 seconds. The display prompts either OT (over thickness) or UT (under thickness). Releasing and pushing the button again advances the tolerance value over a range of 1 to 99%.

As a double metal detector the Model DS1520 can discriminate single, double, and no-metal conditions.

As a coil thickness or weld splice monitor it can detect under, over (weld), and nothing present conditions. The detection system is not considered a precision thickness measuring device. However, if metal passing between it probes is vertically confined to 5 mm (.200"), it is able to detect a change of .0250 mm out of .254 mm (.001" out of .010"), .125 out of 2.5 mm ( 005" out of .100") & .4 mm out of 6 mm (015" out of .250).

The NOMINAL Tracking feature adjusts for acceptable variations in the nominal thickness.

No need to worry about loosing values. Nonvolatile memory stores all settings if power is lost. Its a great value. |

Model P70A |

|

|

| |

| Dual Probe Double Metal Detectors for Ferrous and Non-Ferrous Standard Thickness

Features

- Same as DS1510 with adjustable OVER, UNDER threshold and with a Model SM10 Selection Module, it stores up to 10 separate application values.

- Separate adjustments for OVER & UNDER threshold. Adjust reject thresholds in 1% increments up to 99%.

- Separate relay outputs for OVER and UNDER rejects

- Optional Manual or Automatic calibration eliminates setup time and permits optimized settings

- Self diagnostic messages quickly isolate system problems, errors and failures

- Automatic frequency and gain settings provide simple, quick and accurate startup

- Operating Power 90 - 240 Volts AC @ 50-60 Hz.

- Compact Size, (210 mm x 170 mm x 50 mm) to fit in tight spaces

- Quick connect terminals for fast replacement and to reduce downtime

- Latched or momentary output option

|

|

- Power Input: 100 to 240 VAC, 50/60 Hz 300 mA operating load.

- Output: 2 SPDT contact relays Max load: 10 Amps @ 240 V AC 8 Amps @ 24 V DC ½ HP @ 240 V AC.

- Output Fail-safe: defaults to reject w/power off

- Output Response: adjustable to < .030, .100, .500, 1 second.

- Probe Assessment: * determines probe type, probe separation, nothing present signal level when powered up or AUXIN input is closed.

- Thickness Range: .5 to 2 ounce copper plate. Up to 100 nonmagnetic stainless steel. Magnetic SS see DS1500 Family.

- Probe Models: all probes beginning with P15, P70, P1000.

- Probe Separation: 12 mm to 75 mm (.5 to 3”) or more. Max. varies w/(metal, thickness & probe, separation). Maximum range is realized with Model P15CS, P70CS, P1000B.

|

- Calibration: push-button switch used to change time interval or manually initiate calibration. *Two sample calibration. Manually place two samples between probes, push Cal. button.

- Enable Input: enables controlled output at specific interval.

- Reject Threshold: variable from 1 to 99% between two sample calibration. Separate adjustments for OVER and UNDER.

- LED Indicators: (1)Green for single, (3)Amber for OVER, UNDER & NOTHING detected.

- Sensor Operation: eddy Current in metal impedes signal from transmitter to receiver. Impedance changes as metal thickness changes.

- Display Indication: 2 digit LED, alphanumeric, .5 inch high. Setup menu, calibration mode, operating probe signal strength, fault codes.

|

|

|

|