Magnetic Separators |

|

|---|---|

|

|

|

MagSep The Mayfran MagSep, commonly referred to as a magnetic drag conveyor, is a good choice for handling cast iron. However, it can be used for other types of ferrous materials under two inches long. Theory of Operation: |

|

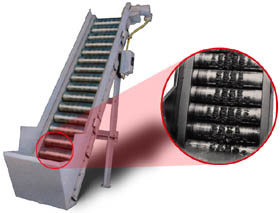

The Magnetic Roller Separator The Mayfran Magnetic Roller Separator Conveyor is ideal for handling small ferrous chips to approximately two inch lengths. It is recommended for applications where coolant cleanliness to 100 micron nominal is a critical factor. |

Theory Of Operation:The conveyor is made up of tubular stainless steel rollers with permanent magnetic cores. Each core consists of stationary magnets, with strength gradually diminishing in the direction of roller rotation. Ferrous chips are magnetically attracted to the roller's surface. as the roller turns, the particles are transported from a strong to a weak magnetic field. The strong magnetic field of the next roller attracts the particles from the preceding roller's weaker field. as the chips pass from roller to roller, coolant drips off, resulting in a fairly dry discharge. |

|

|

Mayfran Magnetic Spiked Belt Separator Conveyor The Spiked Belt Separator easily handles mixed bushy chips and turnings mixed with bar ends or parts while maximizing coolant recovery. How it works:

|

|

The belt, made of polyurethane-coated polyester, travels along a powerful magnetic bed attracting ferrous material to the belt. The belt is interspaced with stainless steel spikes to snare and move bushy turnings. As the belt moves chips up an incline, coolant drains back for recovery. After discharging material, the belt passes over a strong magnetic drum removing any chips still clinging to the belt. Fines suspended in the coolant are attracted to the belt for further discharge. Fines that are attracted to the surface of the magnetic bed are cleaned with scrapers on the underside of the belt. A magnetic drum at the tail end of the conveyor traps the remaining fines. |

|

The Mayfran Magnetic Screw Conveyor The Mayfran Magnetic Screw Conveyor is a low cost, space saving conveyor for ferrous chips under one inch long and low coolant volume. Theory Of Operation:The conveyor employs a magnetic core inside a fixed stainless steel tube. The magnetic core attracts the ferrous material and conveys it along the surface of the tube in a spiral progression. The core is driven by a small, directly coupled, low voltage motor. A variable speed controller tailors the output to your requirements |

|

|---|